Another factor to consider is the material of the hose. Most pressure washer hoses are made from either rubber or PVC. Rubber hoses are more durable and can withstand higher temperatures, making them ideal for heavy-duty cleaning. On the other hand, PVC hoses are lighter and more flexible, which makes them easier to handle but may not be suitable for extreme conditions.

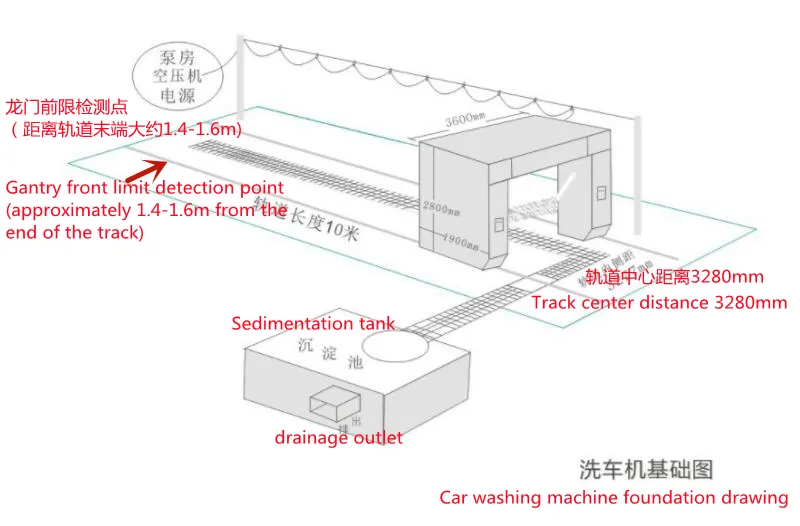

rollover car wash

High-pressure electric car washing machines operate by generating a powerful stream of water that can effectively remove dirt, grime, and stubborn stains from the car's surface. Unlike traditional washing methods, which often rely on buckets and sponges, these machines use a concentrated jet of water, dramatically reducing the time and effort required to achieve a spotless finish. As a result, car owners can enjoy a quick and hassle-free cleaning experience.

One of the standout features of contemporary automated car wash equipment is its integration with smart technology. Many modern systems are equipped with sensors and cameras that enhance the cleaning process. These sensors can detect dirt levels and adjust water pressure accordingly, ensuring that each car receives a customized wash. Additionally, some systems utilize computer algorithms to optimize the sequence of cleaning actions, resulting in reduced water and energy consumption.

automated car wash equipment

Car wash tunnels have revolutionized the way we think about vehicle maintenance and cleanliness. A well-designed car wash tunnel layout is essential for maximizing efficiency, minimizing wait times, and ensuring the best possible cleaning results. Understanding the components and flow of a car wash tunnel is crucial for both operators and customers.

The design of the volute is crucial for the efficiency of the pump. A well-designed volute minimizes flow separation and turbulence, ensuring a smooth transition of the fluid from the impeller to the discharge pipe. The volute shape is typically spiral, which facilitates a uniform flow distribution. If the volute is improperly designed, it can lead to inefficiencies such as cavitation, vibrations, and noise, significantly affecting the pump's overall performance.

volute in centrifugal pump